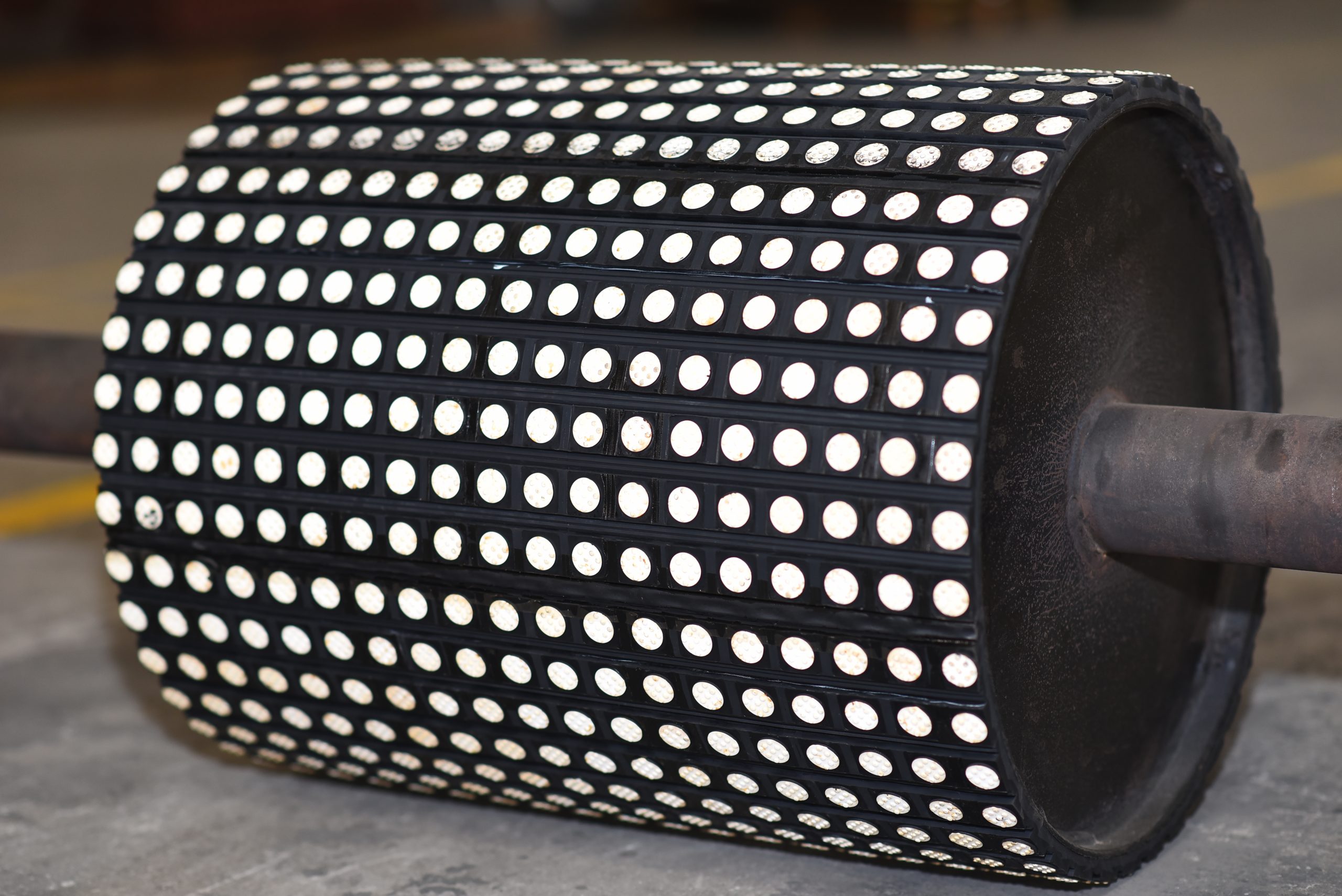

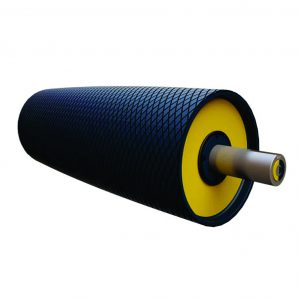

Porcelain coated roller (Ceramic)

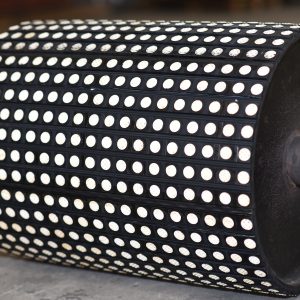

Ceramic coated rollers (porcelain) are made by using the method of gluing ceramic rubber sheets onto the roller surface. Ceramic coated rubber sheets (porcelain) are a combination of ceramic plates on the surface of a special rubber sheet, according to a certain layout (in squares, fillings, circles…) by advanced hot vulcanization technology.

The biggest difference in ceramic coated rollers of 75 Rubber Co., Ltd. is the hot vulcanization method, which instantly molds ceramic rubber sheets onto the roller surface instead of using cold glue technology. Therefore, the bond between the ceramic rubber layer and the roller reinforcement ensures high homogeneity, withstands great tension on the surface and greatly increases the life of the roller.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.