Băng tải cao su cốt sợi cáp thép chịu nhiệt

Tình trạng: Còn hàng

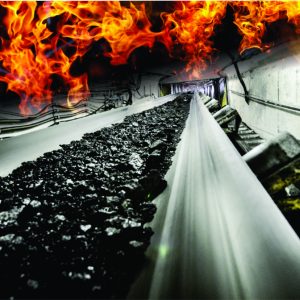

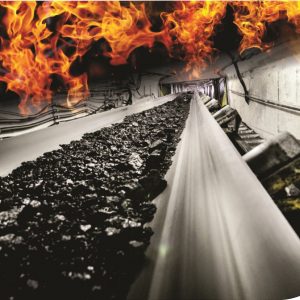

Mã số sản phẩm: Băng tải chịu nhiệt được chế tạo bởi lớp cốt chịu lực bên trong và cao su bề mặt có khả năng chịu được nhiệt độ sử dụng rộng rãi trong các ngành sản xuất xi măng để tải Clinker nóng và các ngành sản xuất phân bón, hoá chất, nguyên nhiên liệu, chuyên chở vật liệu xây dựng (Bitum, Asphalt…)

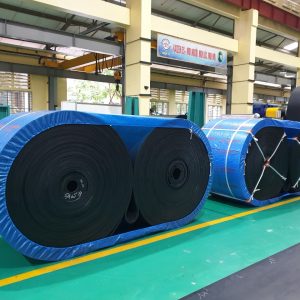

Thương hiệu : Cao Su 75

Danh mục: Băng tải cao su

CHI TIẾT SẢN PHẨM

Phân loại băng tải thép theo mục đích sử dụng:

- Băng tải cao su cốt sợi cáp thép chịu nhiệt

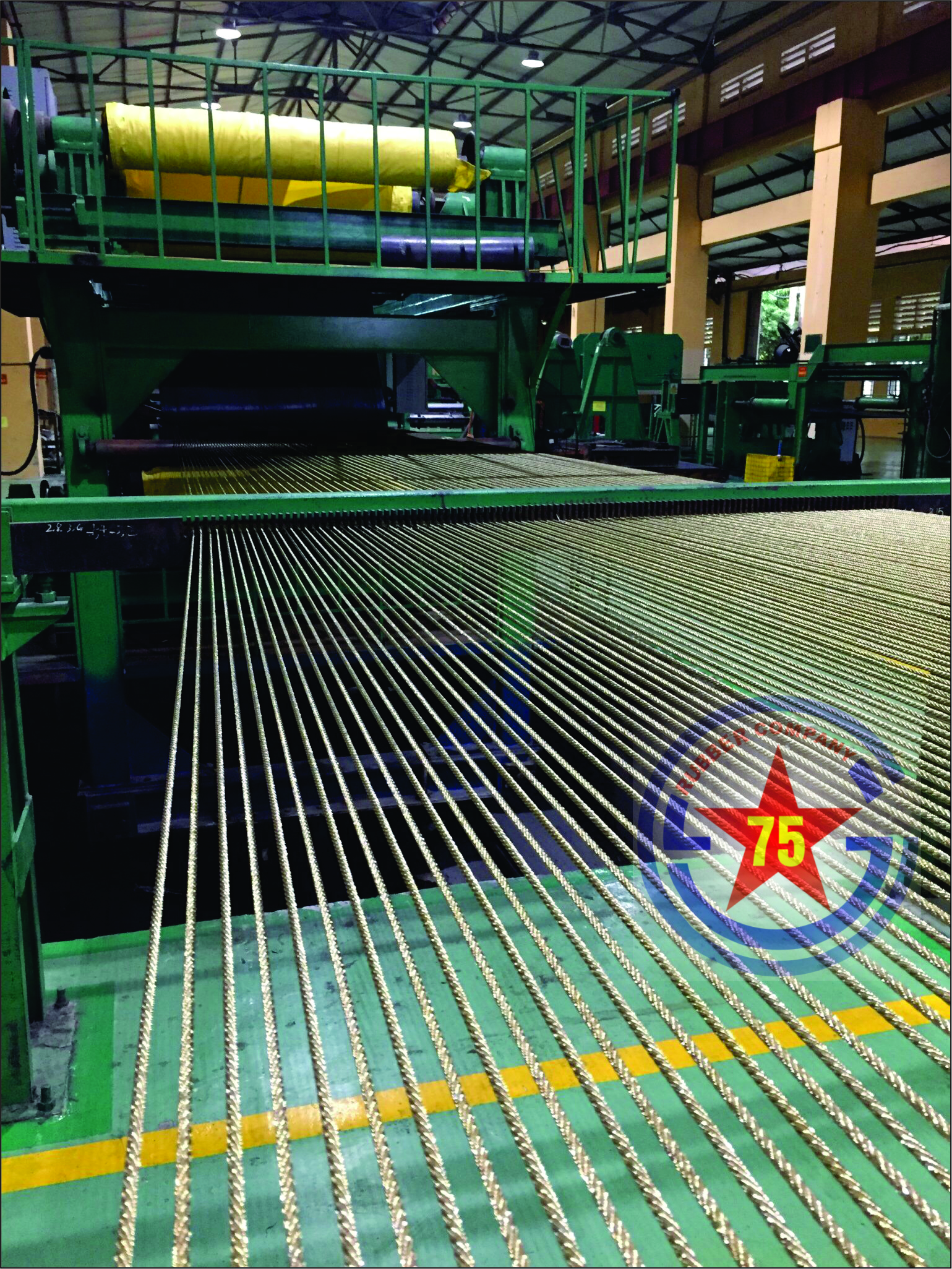

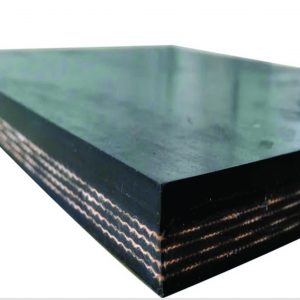

Kết cấu cơ bản của băng tải cao su cốt sợi thép

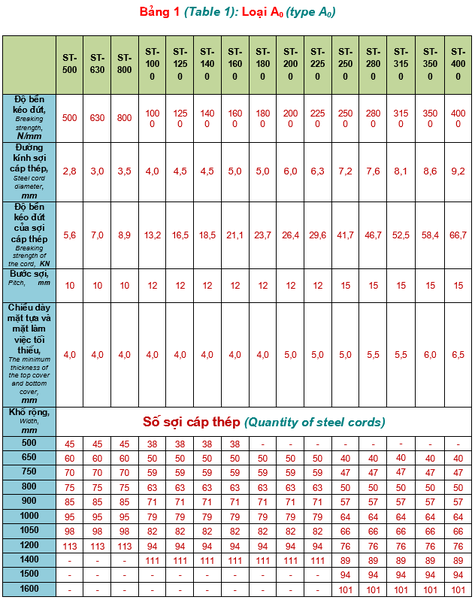

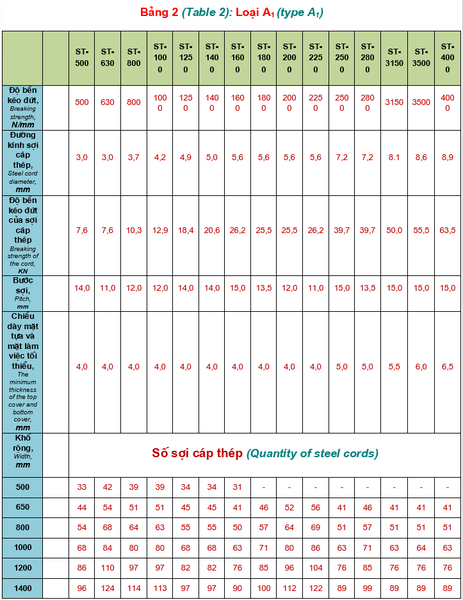

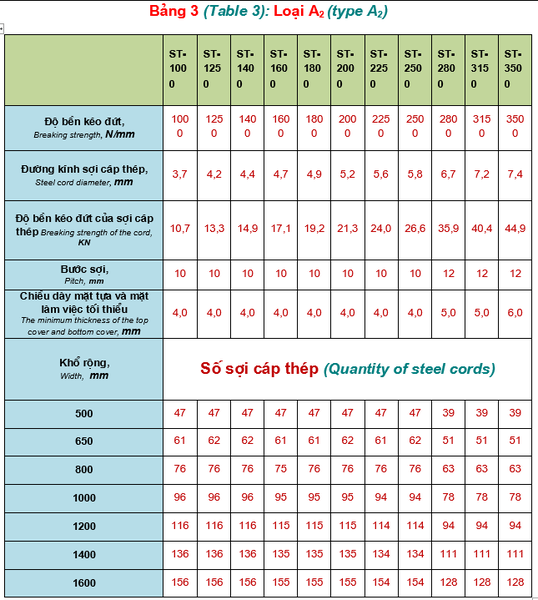

MỘT SỐ THÔNG SỐ KỸ THUẬT CƠ BẢN

| Số sợi cáp thép lớn nhất | 156 sợi |

| Chiều rộng lớn nhất | 2200mm |

| Chiều dày nhỏ nhất | 11mm (không khống chế lớn nhất) |

| Cuờng lực băng lớn nhất | ST3500 |

| Chiều dài cuộn tiêu chuẩn | 200m (Có thể sản xuất theo yêu cầu khách hàng lên đến 400m) |

| Đường kính sợi cáp trong | 2,7 – 8,1mm |

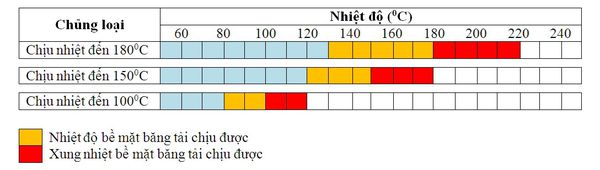

MỘT SỐ CHỈ TIÊU CHO CAO SU MẶT

| Chủng loại băng tải | Độ bền kéo đứt (MPa) |

Độ dãn dài (%) | mòn (mm³) Độ mài |

| Băng tải mài mòn cấp D (JIS K 6322:2011) | ≥18 | ≥400 | ≤100 |

| Băng tải chịu nhiệt đến 180*C (Xung nhiệt 2200C) (JIS K 6322:2011) |

≥16 | ≥450 | ≤150 |

| Băng tải DIN 22102 (DIN W) | ≥18 | ≥400 | ≤90 |

| Băng tải DIN 22102 (DIN X) | ≥25 | ≥450 | ≤120 |

| Băng tải DIN 22102 (DIN Y) | ≥20 | ≥400 | ≤150 |

| Băng tải DIN 22102 (DIN Z) | ≥15 | ≥350 | ≤250 |

| Băng tải chống cháy (DIN K) | ≥20 | ≥400 | ≤150 |

THÔNG SỐ KỸ THUẬT VÀ TIÊU CHUẨN KIỂM TRA

| STT | Thông số kỹ thuật | Tiêu chuẩn kiểm tra |

| 1 | Chiều rộng băng | JIS K 6369:2007 |

| 2 | Chiều dày băng | JIS K 6369:2007 |

| 3 | Chiều dày mặt làm việc | JIS K 6369:2007 |

| 4 | Chiều dày mặt tựa | JIS K 6369:2007 |

| 5 | Độ bền kéo đứt băng | JIS K 6369:2007 |

| 6 | Độ dãn dài khi đứt | JIS K 6369:2007 |

| 7 | Độ dãn dài khi làm việc | JIS K 6369:2007 |

| 8 | Độ bám dính giữa lớp cao su mặt và lớp cao su lõi | JIS K 6369:2007 |

| 9 | Độ bám dính giữa lớp cao su lõi và cốt thép | JIS K 6369:2007 |

| 10 | Độ bền kéo đứt giữa cao su bám dính và sợi cáp thép | JIS K 6369:2007 |

| 11 | Mối nối băng tải thép | JIS K 6369:2007 |

English

English

Đánh giá

Chưa có đánh giá nào.