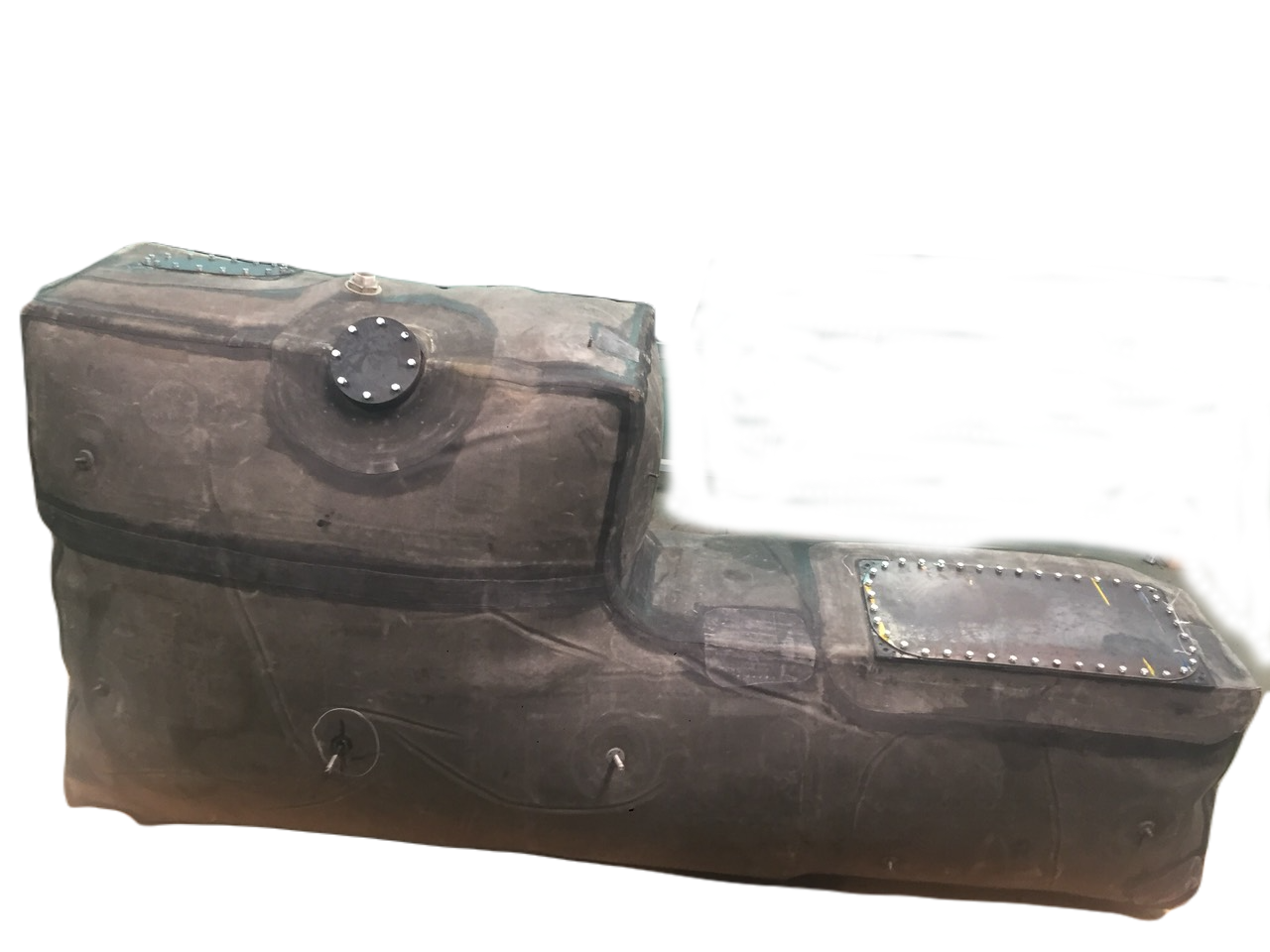

Rubber oil tank (K28)

Factory Z175/General Department of Defense Industry has successfully researched and manufactured many lines of soft oil tank products for different types of aircraft equipment to meet the usage requirements of units in the Army. Unlike traditional oil tanks made of metal, fuel tanks for aircraft such as UAVs, K28, K-32 helicopters, SU, AH aircraft…

English

English

Đánh giá

Chưa có đánh giá nào.