Internal News

Innovation of technology, quaylity improvement of undersea insulation – oil coated pipes for VIETSOPTRO JOINT VENTURE

75 Rubber Company Limited of Ministry of National Defense with the goal throughout is to build the Company into a high-tech rubber production base of the army. Deeply grasping the view of closely combining defense production with economy, economy with national defense, taking the task of defense production as the focus, expanding production and business to maintain capacity and staff, in the last years, with the attention and investment of the State, the Ministry of National Defense and the General Department of Military Industries and Manufacture, the Company has invested in renovating and building new infrastructure, investing in new advanced equipment and modern production lines to expand and improve production capacity; focusing on investing in scientific research, technological innovation, and putting the IT system into operational management.

Along with that, in order to improve production and business efficiency, the Company’s leaders have applied new management and Kaizen – 5S program, rearranged technology ground, rationalized production, focused on training, fostering and building a team of technical staffs, managers, and market staffs to meet the Company’s development requirements in the new situation. With a team of highly qualified technical staffs, the Company has researched many topics at the Ministry of National Defense, the General Department levels and many grassroots-level topics applied to production, contributing to increasing labor productivity, improving product quality, saving a lot of materials and labor. As a proof of the achieved results, in May 2019, the Company implemented a contract to manufacture Undersea Insulation-Coated Oil Pipes for Vietsovptro Joint Venture, with a total output of 7000m, required contract execution time is 45 days (including shipping time). Determining that this is a product requiring high technical requirements, fast delivery schedule, the Leaders and Commanders of the Company have paid attention to leading and preparing elements for production (equipment, materials, personnel, etc…), focusing on directing research and innovation, improving product quality, organizing the launching of peak emulation sessions, mobilizing officers and employees to actively work overtime and increase the hours to ensure punctuality, quality according to customer requirements. As a result, labor productivity increased by 1.5 times; the number of employees decreased by 30% compared to before, after 40 days of production, the company completed the order for the Vietsovptro joint venture, maintaining the production of traditional products to ensure quality and progress for customers.

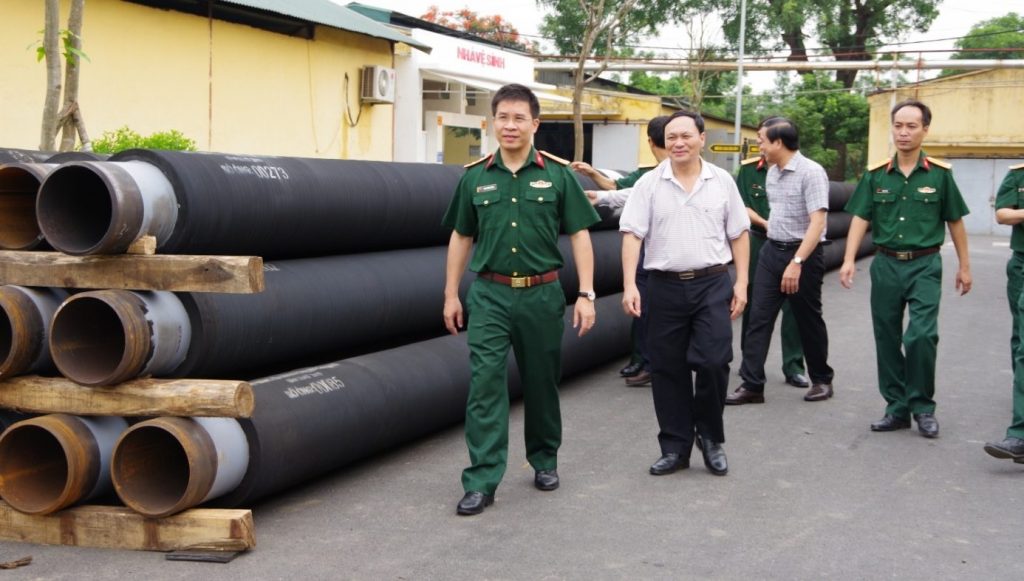

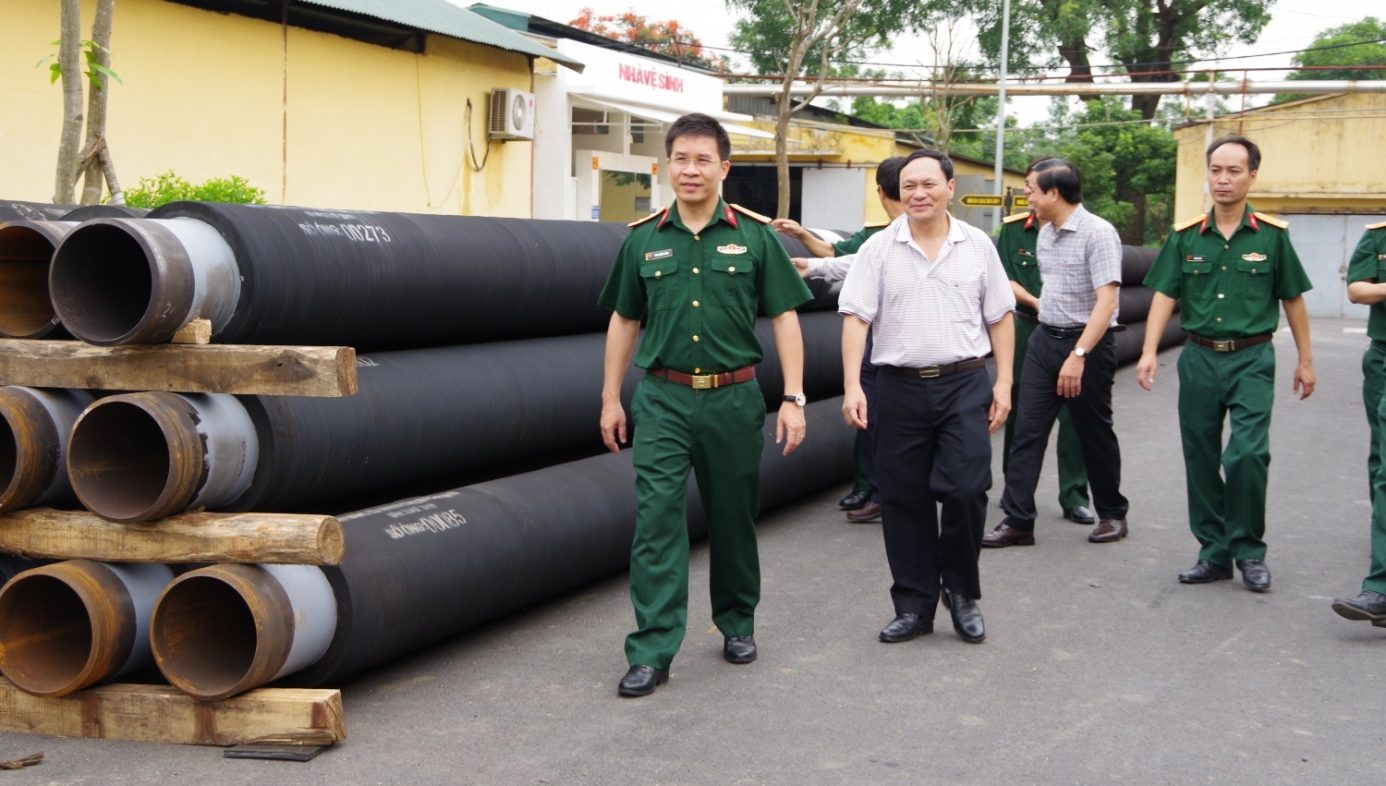

Senior Colonel Phan Chien Thang – Company Director and Vietsovptro Joint Venture team inspected production

These achievements are due to the attention of the Ministry of National Defense, the General Department of Military Industries and Manufacture, the dynamism, creativity and self-reliance of the Leaders, Commanders, and staffs; assertiveness, boldness in setting out the right guidelines and directions, it is believed that in the coming years, the Company will continue to make steady development steps, meeting the requirements of serving for the army and the domestic economic sectors and international economic integration.

SOME FIGURES ON PRODUCTION OF UNDERSEA INSULATION-OIL COATED PIPES

Tiếng Việt

Tiếng Việt